Visual controller solution

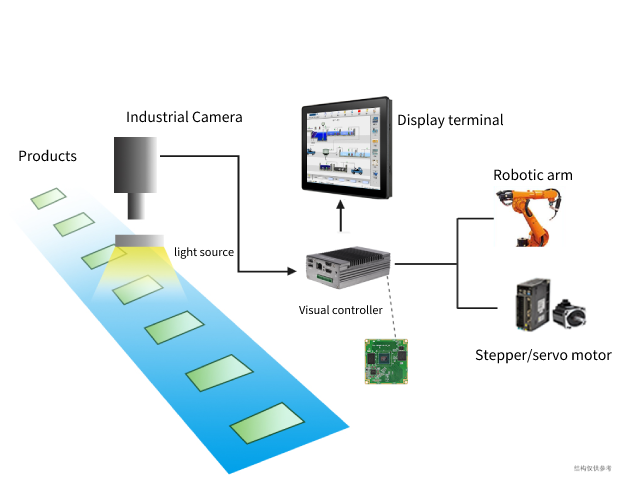

With the rapid development of industrial intelligence, machine vision has realized the functions of workpiece identification, location positioning, size measurement, quality defect detection, high-precision detection, code reading identification and tracing, automatic sorting and handling in industrial production, and is widely used in automobile, electronics, clothing, food, medicine, packaging, logistics and other industries. Machine vision system refers to converting the target object into image signal through CMOS or CCD equipment, then transmitting it to special image processing system, and converting it into digital signal according to pixel distribution, brightness, color and other information; Image system analyzes and judges these signals, and then displays them on the screen or controls the action of field equipment according to the judgment result.

Machine vision system needs to collect, transmit and process a large amount of image data during operation, which puts forward higher requirements for system software and hardware. Technology upgrading is the core driving force for the development of machine vision. With the maturity of embedded technology, deep learning, AI algorithm and other technologies, the intelligent development of machine vision image analysis and processing capability has been promoted. In the machine vision system, HEBG provides reliable ARM embedded hardware to be applied to the machine vision controller, which integrates the functions of image acquisition, processing, control and communication to help realize the high efficiency and stable operation of the vision system. HEBG launched IAC-IMX8MP-CM core board and IAC-IMX8MP-Kit evelopment Board, which can realize the functions of image acquisition, algorithm processing, display and control, and be applied to Machine Vision controller solutions.

Visual controllers need professional visual control and high-performance image processing capabilities. The core board of HEBG IAC-IMX8MP-CM s designed based on the NXP I. MX8M Plus Processor. It has a powerful quad-core Cortex-A53 core and a Cortex-M7 controller. It integrates the Neural Processing Unit NPU and provides 2.3tops computing power. The combination of multi-core CPU, high-performance GPU, ISP and NPU provides powerful computing power for machine vision algorithms.

I. MX8M Plus processor integrates two ISPs, supports simultaneous input of two cameras, and can be connected to industrial cameras through USB or Ethernet ports; The input rate of ISPs is as high as 375m pixels/s, providing sufficient processing capability, capable of carrying out complex image processing tasks and realizing accurate machine learning recognition and processing; Meanwhile, the integrated ISPs can reduce the overall complexity, cost and power requirements of the machine vision system.

Visual controller requires to provide comprehensive common interfaces of visual system, such as network port, USB interface, light source interface, GPIO interface, etc. I. MX8M Plus processor has rich interface resources, two gigabit network ports, two CAN-FD interfaces, USB 3.0/2.0, RS232/485, GPIO, a variety of display interfaces, etc. It can connect cameras, light source controllers, PLC controllers, displays and other devices through various serial ports. In addition, the processor also provides PCIe3.0 interface, which can connect various functional expansion cards such as image acquisition cards, etc. to improve the data processing capability of machine vision system.

Visual controllers are mostly used in industrial production, so they need to face harsh factory environment. In order to ensure the high reliability and stability of the system in the industrial environment, I. MX 8m Plus processor supports DRAM inline ECC to detect and correct memory errors; It supports industrial temperature width of-40℃ ~ + 85℃, which is suitable for all kinds of industrial environments; The processor supports TSN Ethernet connection, which helps to ensure data transmission at the correct time and supports time-sensitive requirements of factories and workshops. Cortex-M7 real-time control kernel can handle local real-time control tasks and provide reliable local control networks for industrial applications with CAN-FD interfaces.

I. MX8M Plus supports Linux operating systems, provides SDKs for Call Control adaptation, and provides flexible development to make the hardware layer fully compatible with machine vision system software.

With the deepening of automation and intelligence in China's industrial manufacturing field in the future, machine vision will be more and more closely related to various fields.